Table of Contents

Using the SSRL Automated Mounting (SAM)

system

SAM is a completely integrated hardware and software system for

mounting and dismounting pre-frozen protein crystals and screening

samples for x-ray diffraction quality in a fully automated or

semi-automated fashion. SAM is installed on all of the SSRL

macromolecular crystallography beam lines and is seamlessly integrated

into the beamline control and data analysis software. Since upgrading

the robot system in 2014, the screening sequence (comprising crystal

mounting, automatic sample loop centering in the x-ray beam, video and

diffraction image acquisition at 0 and 90 degrees, and

dismounting) may take less than

one minute per crystal. The diffraction images are analyzed and autoindexed on

the fly.

Samples may be stored in either SSRL cassettes or

Uni-Pucks for use with SAM. If you are scheduled beam

time with use of the robot sample mounting system, a cassette kit will

be lent to you.

The following sections describe how to prepare your crystals for

data collection using the SSRL robotic sample mounting system. Follow

these instructions to prepare the sample pins, mount

them in an SSRL cassette or Uni-Puck and ship them to the SSRL.

For additional information on the SAM system, see also the guide to

automated sample

screening. There are also

video tutorials

illustrating the sample preparation, sample container loading using SSRL cassettes, and Unipucks and use of the SAM system for data collection.

For

information about the cassette kit tools, including drawings and

vendor information, see the SAM hardware web

pages

Figure 8:

The two types of container for automated sample mounting at SSRL

|

|

Sample pin selection and preparation

To have a successful experiment proper sample pin preparation is

essential. The majority of problems we have observed with SAM have

been related to use of improper sample pins. To avoid these problems

please read the following directions.

The SSRL system supports only Hampton-style CrystalCap Copper Magnetic

pins or CrystalCap Magnetic pins. The allowed pins

sizes are 16 or 18 mm. The 18 mm size copper pin

is preferred.

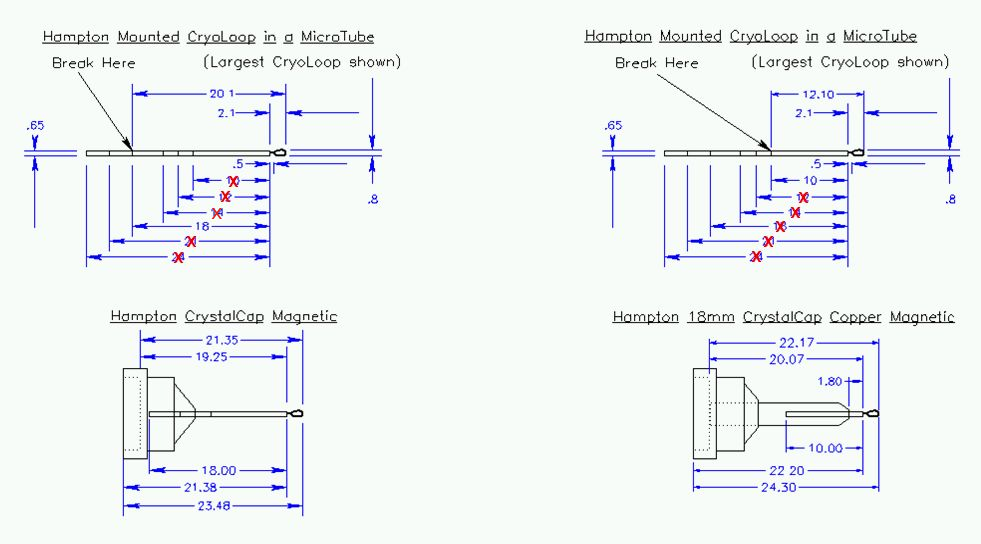

Figure 9:

Preferred size of pin. Hampton cryo-loops should be cut at

the segment closest to the loop for use with the CrystalCap Copper pin

bases, provided with the cassette kits. Do not exceed the maximum

MicroTube length shown in the diagram! Unacceptable lengths are

marked with a red x. The 11 mm MiTeGen Micromounts and meshes should

be used with the CrystalCap Copper pin base; longer Micromounts

will need to be cut to the proper length before inserting into this pin

base.

|

|

Compatible

Hampton-style sample pins may be purchased from a number

of vendors including Hampton

Research,

MiTeGen, Crystal

Positioning Systems

or

Molecular Dimensions.

If sample pins are purchased from MiTeGen, use the B1, B1A or

B3S

with the 18mm

MicroMounts, MicroLoops, MicroMeshes or MicroGrippers. The B1, B1A, B3A and B3

bases can also be used with 19 mm mounts. The older B2 base can be used with

11 mm Micromounts and 10 mm nylon loop mounts. Please note that the

SSRL loop-centering routine, based on visual analysis, is not yet optimized for use

with the MiTeGen MicroMount, these mounts, as well as the loops are

well suited for

rastering. SPINE-standard pins can not be used with

SAM.

Figure 10:

Commonly available pin types

|

|

We recommend using Hampton-style Copper Magnetic pins because no laser

etched lines are exposed. These are the pins supplied with the

cassette kit. The microtubes used with Magnetic pins can

sometimes break off if bumped.

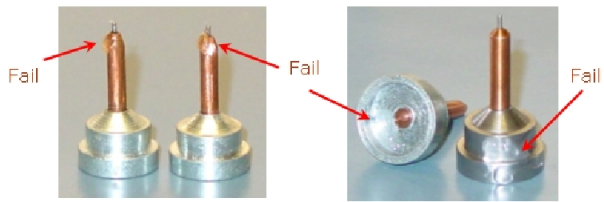

Figure 11:

Broken microtubes used with Magnetic pins can make the pin

jam inside the cassette port, stopping the robot.

|

|

Microtubes should be affixed inside sample pins using epoxy.

Any epoxy with a curing time between 5 minutes and 24 hours should

work well for this purpose. We have found that superglue and superglue

gel is less reliable than epoxy for affixing microtubes. A number of

failures with the SAM system have been attributed to using other types

of adhesives on sample pins such as wax, nail polish, and Duco cement.

These should not be used.

Figure 12:

Use Epoxy to affix the microtubes to the sample pins. Glues

other than Epoxy have been observed to cause sample mounting

errors.

|

|

If an adhesive other than Epoxy has been used to affix the

microtubes to your sample pins, please let your user-support person

know in advance of using them. These pins may cause problems with

SAM.

Be careful not to use pins with excess epoxy on the pin base or

postpin-excess and do not get grease or excess cryo-protectant on the pin body.

At liquid nitrogen temperatures, grease from crystallization trays

gets rock hard. If you continually reuse your pins, please also

inspect them for corrosion and loose microtubes. Anything that changes

the outside form factor of the sample pin could cause the pin not to fit properly in the SAM robot tongs.

Warning: Do not use pins with excess epoxy on the copper post.

If you would like to mark your sample pins different colors, use

permanent marker for this purpose. Paint or nail polish should not be

used as this can change the form-factor of the pin or be sticky.

Hampton Research now sells a new pre-assembled Copper Magnetic sample

pin (catalog number HR5-112) which is already color coded according to

the size of the nylon loop attached. It also has an alpha numeric

code and bar code.

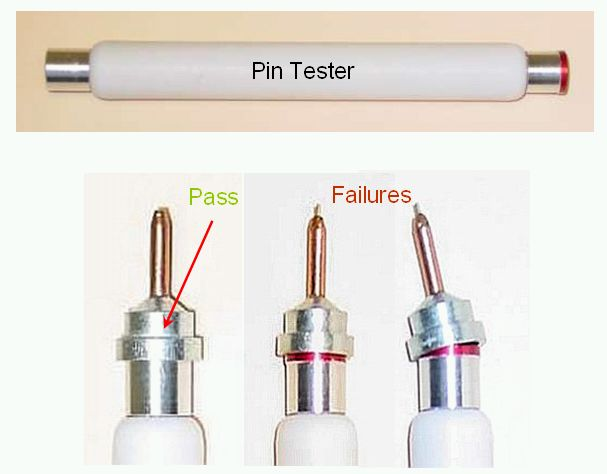

All pins must be tested to ensure they fall within the allowed

tolerances. We have found some irregular pins that if used would

damage the SSRL sample mounting system. To test your pins, place them

on the end of the Pin Tester magnetic tool on the red line.

Only use pins that completely cover the red mark without forcing. Pins

that fail this test should not be used!

Figure 13:

Use this tool (included with the SAM kit) to test all your

pins before use with the SAM robot

|

|

Broken micro-tubes and torn nylon loops are usually a result of

mishandling sample pins in preparation for reuse. In particular pins

should not be piled together in a container when washing and drying

them. To wash pins, place them individually on a magnetic tray. Hang

the tray upside down to dry the pins. It is important to store your

sample pins in a safe place when they are not in use. The

microtube storage rack is a useful storage location for extra pins.

Figure 14:

Storing pins for re-use.

|

|

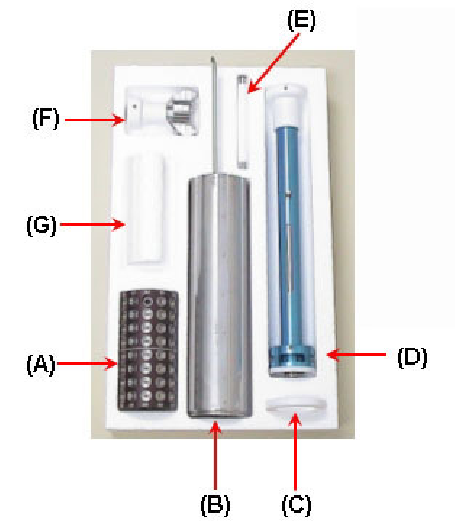

If you

are scheduled beamtime with use of the robot sample mounting system, a

cassette kit will be lent to

you.

Figure 15:

Cassette Kit: (A) Sample Cassette and 96 Hampton pins

(microtubes and loops not included) (B) Dewar Canister - replaces

stock canister in dry shipping dewars (C) Teflon Ring - to support the

canister in the shipping dewar (D) Transfer Handle - for transferring

cold cassettes (E) Magnet Tool - to mount pins in cassette and to the

test size of pins (F) Guide Tool - to aid in mounting pins into cassettes

with the magnetic tool (G) Styrofoam Spacer - to keep the cassette in

place when shipping one cassette; not shown: A dewar for mounting

crystals into the cassette.

|

|

The cassette contains 96 sample ports each port contains a ring

magnet which holds in the sample pin. A cutaway view of the cassette

is shown below. The ring magnets are shown

in green. The magnets are held in place by a polycarbonate washer

shown in white. The washers are removable so any broken ring magnets

may be replaced.

Figure 16:

Cassette diagram. The ring magnets are shown in green and the

washers holding the magnet are shown in white

|

|

Cassettes should not be stored where magnetic debris

can get inside the ports. Before using your cassette, it should be

inspected to ensure the ports are all empty.

The transfer handle is used to safely transport cold cassettes.

To attach the transfer handle (D) to a sample cassette

(A) first place the locking pins into the slots

at the top of the cassette. Then push down the handle, and rotate

clockwise until the handle locks in place.

Figure 17:

Attaching transfer handle to

cassette

|

|

The slotted guide tool consists of a long

magnetic wand with two slots in the middle and a loading guide with a track on the handle

that accommodates the slots on the wand tool. To flash freeze samples,

the wand may be inserted into the top of the loading guide. To

transfer pre-frozen samples it is important to keep the samples at

liquid nitrogen temperatures during transport into the cassette. The

wand should be inserted from the side of the slotted guide tool to

keep the sample under liquid nitrogen during transfer. Use the slot

closest to the red (or maroon) side of wand (weak magnet) for loading

samples.

When unloading samples the wand is turned around and the

opposite slot and stronger magnet is used.

The circular cutout in the loading dewar may be used to hold

samples in cryo-vials or pucks for transfer.

The most common problems we see observe with cassette loading is the

accumulation of ice in the liquid nitrogen bath. Ice will stick to

your sample as it is transferred through the liquid nitrogen on the

way to the cassette port. It can also fall inside the cassette ports.

If excess ice is observed in the bath, the cassette should be stored

in a cold dry-shipping dewar and the loading dewar emptied, dried and

refilled with liquid nitrogen before proceeding.

Important: To prevent ice from

accumulating in the liquid nitrogen, the cassette should not be stored

in the loading dewar for more than 20 minutes without exchanging

the liquid nitrogen.

To avoid ice accumulation, it may be useful to

to load cassettes under a fume hood or a dry box (as an example, see

a description of Nham Nguyen's setup at

http://smb.slac.stanford.edu/facilities/hardware/cassette_kit/Ice

free_Nham.pdf).

If not using a fume hood or a dry box,

cover the dewar with the lid when you are not mounting crystals.

To prevent ice from falling into empty cassette ports, some users

advise filling empty ports with blank pins. Each blank pin is removed

just before inserting a sample pin into the port.

Important: Please read the safety notes before

working with liquid nitrogen and make sure you are familiar with the

liquid nitrogen safety procedures at your institution.

- The custom foam dewar should be filled up to the

internal indicator ledge This takes

about 4 Liters of liquid nitrogen; it will be necessary to top off the

liquid nitrogen level after inserting a warm cassette.

Figure 19:

Filling the custom foam dewar

|

|

- Once the dewar is filled and equilibrated, place the cassette

in the dewar and tilt the transfer handle until it rests inside the

side notch. Then push the cassette

forward until the bottom of the cassette is

touching the edge of the dewar.

- The guide tool may be pre-cooled on the side dewar

shelf. To prevent condensation on the metal

portions of the guide, it may be stored on the shelf between loading

samples.

Figure 20:

a. Placing the cassette in the foam dewar. b. Storing the guide tool.

|

|

- Rotate the sample cassette with the transfer

handle to access the desired cassette

port.

- Place the guide tool (F) on the

cassette centered on the port.

Figure 21:

a. Placing the guide tool into the cassette. b.

Putting the pin on magnet tool. c. Picking the

crystal.

|

|

- To flash freeze a sample:

- Put a pin onto the red side of the magnet tool (E)

and pick up a crystal.

- Flash-freeze the crystal by placing the pin

through the handle of guide tool and into the cassette port,

minimizing the time the crystal is in the air.

Figure 22:

Flash freezing the crystal

|

|

- To transfer a pre-frozen sample from a vial (or puck):

- Tilt the vial and use the red side of the magnetic wand tool

to remove the sample pin. Be careful to keep the sample under

liquid nitrogen at all times. (Vials or pucks may be placed in the

round cutout inside the dewar.)

Figure 23:

a. Placing the guide on the cassette. b. Picking

the pin. c. Transferring the pin

|

|

- Slide the lower slot of the magnetic wand tool into the guide

tool while keeping the sample under liquid nitrogen.

Figure 24:

Using the guide slot under liquid nitrogen.

|

|

- Once the magnetic wand tool is in the center of the guide

tool, the wand tool may be pressed against the back of the guide

and pushed downward placing the pin into the port. (It is

sometimes helpful to rotate the wand while it is pushed down to

break any ice that may have formed between the magnetic wand tool

and sample pin.) The magnetic tool may then be pulled up, removed

and the next sample transferred.

Important: It is strongly recommended to test the shipping

dewar

prior to shipping samples to make sure that the samples will be kept cold before

arrival.

For information about loading and shipping samples in the Uni-Puck

see:

http://smb.slac.stanford.edu/facilities/hardware/cryotools/Uni-puck/Uni-puck_Directions.pdf

Important: It is strongly recommended to test the shipping

dewar

prior to shipping samples to make sure that the samples will be kept cold before

arrival.

Storing sample information: The Excel spreadsheet

Sample information is entered into a Excel spreadsheet file. The

spreadsheet has a specific format for use with the SSRL Sample

Database and data collection applications.

The following instructions explain how to download, fill up and

upload a spreadsheet.

- You can download a spreadsheet template for the SSRL cassette, Uni-puck adapter (holding up to four pucks) or SSRL plate from the SSRL Sample Database (New Spreadsheet tab).

If your browser cannot

display Excel spreadsheets, click the Save to file button in the

pop-up menu; navigate in the dialog box to the directory of choice and

click Save.

- Type in the information for the samples in the cassette. Important:

Make sure that ''text'' format is used.

- If you are sending more than one cassettes, use one spreadsheet per

cassette. The Uni-puck spreadsheet holds information for four pucks

(labeled A, B, C and D).

Figure 26:

Formatted Screening System Excel Template.

|

|

See also information on editing the spreadsheet.

Uploading an Excel spreadsheet

Uploading the spreadsheet from a Web browser

Once the Excel spreadsheet has been filled out it can be transferred

to the Sample Database at the URL:

http://smb.slac.stanford.edu/crystal-server/

- Log in to the database interface using your account name and

password. You also need cookies and javascript

enabled in your browser to log in and upload the spreadsheet

- Once you are logged into the system you should see the page

shown below.

Figure 27:

The Sample Database interface.

|

|

- Click on

Upload Spreadsheet. You will be directed to the Upload

Excel File page.

- Enter the name of the spreadsheet (you will need the full

directory path, for example: /home/yourid/filename.xls) or click

on the Browse button to search for the file. If you have trouble

locating the file, verify that the filter for types of files is

*.* or *.xls in the Choose File dialog box. Once the file

is located in the dialog box, select Open.

- Enter the Cassette number in the Cassette Pin box. If the Excel

file does not contain a ContainerID, it will be generated and

assigned the value you enter. On the other hand, if the spreadsheet

already contains a ContainerID, the value you enter here will be ignored.

Do not modify the default Spreadsheet name unless you changed it

in your Excel file.

- To finish

uploading the file to the Database, click Upload. If your

spreadsheet is not in a standard format (e.g., empty or duplicated

CrystalID, no ContainerID) the interface will apply and

display the necessary corrections in a separate page. Scroll to the

bottom of this page and click on Display Cassettes. This will

take you back to the home page, displaying the new spreadsheet

entry.

Figure 28:

Uploaded spreadsheet information.

|

|

- To

screen more than one cassette, click on "Create New Entry" again and upload

the corresponding spreadsheet, etc.

- Entries can be removed from the database by clicking

Delete entry.

Important: If you do not wish to fill up the spreadsheet, it is possible to

use a Default Spreadsheet.

Uploading the spreadsheet from Blu-Ice

Once you beamtime has started and you have been enabled to start

the experiment, it is possible to access the Sample Database directly from

the

screening

tab in Blu-Ice:

Clicking the Web button will

launch a web browser and you can upload the file as described in the

previous section.

Assigning the Excel spreadsheet to a

beamline

The information in the database may be assigned to a

beamline once beamline access has been permitted. On the

Sample Database page, the last entry (Beamline column) is used to assign the Excel spreadsheet to a

particular beamline or to a particular cassette location. A total of 3

cassettes can be placed in the cassette storage dewar and are labeled

'left', 'middle' and 'right'. Select the appropriate position (staff

will let you know which one to use) and

beamline by using the drop down menu. If the assignment fails, ask

the support staff to verify that your account has beamline access.

The spreadsheet assignment can also be done directly from Blu-Ice

using the Cassette drop-down menu.

Using the Default spreadsheet

Sample screening without a spreadsheet is possible, but the

results of the screening will not be saved. To avoid this problem,

log in to the Sample Database interface as described above and click

Use Default Spreadsheet. Select the cassette type (SSRL or Puck

adapter), type in the cassette number if known and click

Submit. A cassette named cassette_template.xls will appear in

your spreadsheet list. The spreadsheet can be assigned to a beamline

and dewar position as usual.

Editing the spreadsheet

The easiest way to make extensive changes to an uploaded

Excel spreadsheet is to download the file to the local computer,

then edit it and upload the modified file as explained in the

previous section. The link Download Original Excel

file can be used to retrieve the original uploaded file, without any

edits or results. If you wish to modify the file after screening

results are available, use the Download Results link instead.

You can edit the Excel file on the Unix beamline computer with the

LibreOffice software. To run LibreOffice from the beamline

computers type:

% libreoffice filename.xls

It is also possible to edit selected fields for a sample

by clicking on View/Edit. This displays an HTML version

of the spreadsheet

Figure 29:

Editable HTML version of the spreadsheet.

|

|

- Check the Port containing the sample you wish to edit

- Click on the Edit Crystal button on top of the

spreadsheet.

- Edit the information in the field(s) of your choice

- Click on Save changes to save your edits or Cancel

to reset the old values.

- Download the modified spreadsheet to the local computer by clicking on

the Download Results link.

During the experiment, Blu-Ice can also be used to edit

selected fields. Consult the

Blu-Ice

documentation to find out how to edit the spreadsheet on these applications.

|

![\includegraphics[width=0.6\textwidth]{images/epoxy.ps}](img10.png)

![\includegraphics[width=0.6\textwidth]{images/glues.ps}](img11.png)

![\includegraphics[width=0.6\textwidth]{images/cassette-cutaway.ps}](img12.png)

![\includegraphics[width=0.8\textwidth]{images/p10.ps}](img18.png)

![\includegraphics[width=0.2\textwidth]{images/p16.ps}](img23.png)