Cryogenic Shipping Dewar

Testing and Shipping

Introduction

Safety and Precautions

Obtain a Dry-Shipping

Dewar

Find the "Empty Weight" of the Dewar

Properly Charge the Dewar

Inspect for Catastrophic Vacuum Failure

Measure Liquid Nitrogen Loss Levels

Find the "Charged Weight" of the Dewar

Shipping Dewars to SSRL

To avoid sample loss during shipping to SSRL, it is

important to check that your dry-shipping dewars are functioning

properly before use. We strongly recommend testing that the dewar can

maintain cryogenic temperatures for the duration of transit time.

Shipping dewars to SSRL often requires 2 to 3 days of transit

time. Occasionally problems with the shipping company can result in

shipments that take more than a week.

The following directions will describe 1) how to obtain

a dry-shipping dewar compatible with the SAM system, 2) how to test your

dry-shipping dewars for performance, and 3) how to ship samples to SSRL for

remote access data collection. Always plan ahead to allow adequate time

to implement the procedures described in this section before samples need to be

shipped to SSRL.

Dewar performance ultimately depends on how long

samples can be stored in the dewar at cryogenic temperatures. Sample storage time will be

degraded by either an excessive liquid nitrogen evaporation rate or a

reduced holding capacity for liquid nitrogen. The liquid nitrogen

evaporation rate is influenced by the integrity of the insulating

vacuum in the dewar. In general, performance degradation can be attributed to either 1)

catastrophic or gradual vacuum loss or 2) accumulation of moisture in the

liquid nitrogen absorbent material or 3) damage and loss of portions of the

absorbent material.

We recommend that you check the performance of your

dry-shipping dewars at least every 6 months and ideally before each use.

Use

this

worksheet to assist you with dewar testing. Please note that this

worksheet is NOT a substitute for reading the directions; it is merely a

device that may be useful in testing the performance of your dewar.

-

Handle the dewar with care. A strong impact to the

outside of the dewar or the neck can cause vacuum failure.

-

Important:

Read the

safety notes before working with liquid nitrogen and make sure you

are familiar with the liquid nitrogen safety procedures at your

institution.

-

Avoid spilling liquid nitrogen over the vacuum plug

near the top of the neck. Exposure of the vacuum plug to liquid nitrogen

can shrink the seal causing air to leak into the insulating vacuum space

reducing the performance of the dry-shipping dewar. A protective cover

for the vacuum plug can be made from Styrofoam.

A dry-shipping dewar is used to ship

samples at cryogenic temperatures in a safe manner without the

possibility of spilling liquid nitrogen out of the shipping container

during transport. The shipping dewar contains a liquid nitrogen

absorbent material that must be properly charged with liquid nitrogen

before use. A properly charged and well functioning dry-shipping dewar will keep crystals at temperatures below 90 K for at least a

week.

Two types of dry-shipping dewars are

approved for shipping the SSRL crystal storage cassettes and uni-pucks which

are used by the

Stanford Automated Mounter (SAM) for remote access data collection.

These are the Taylor Wharton CX100 and CXR100R and the MVE SC4/2V dewars:

Taylor-Wharton Cryogenics

4075 Hamilton Boulevard

Theodore AL 36582

Tel: 1-251-443-8680

Customer Service: 1-800-898-2657

Web: http://www.taylorwharton.com/

Email: twsales@taylorwharton.com

Taylor Wharton CX100 Shipping Dewar

MVE Biological Systems Applied Technologies

Division,

Chart Industries Inc.

3505 County Road 42

West Burnsville, MN 55306-3803

Phone 1-952-882-5000 1-888682-2796

Web: http://www.chart-ind.com/

MVE SC 4 2V Shipping Dewar

How to Test Your Dry-Shipping Dewars for Performance

There are 5 steps required to complete the testing process: 1) find the

empty weight of the dewar, 2) properly charge the dewar, 3) inspect for

catastrophic vacuum failure, 4) measure the liquid nitrogen loss level and

5) determine the charged weight of the dewar.

1)

Remove the dewar from the shipping container and measure the empty

weight of the dewar without the lid (remove any cassettes, canisters, Teflon

rings, etc.). Make sure the dewar is at room temperature.

2)

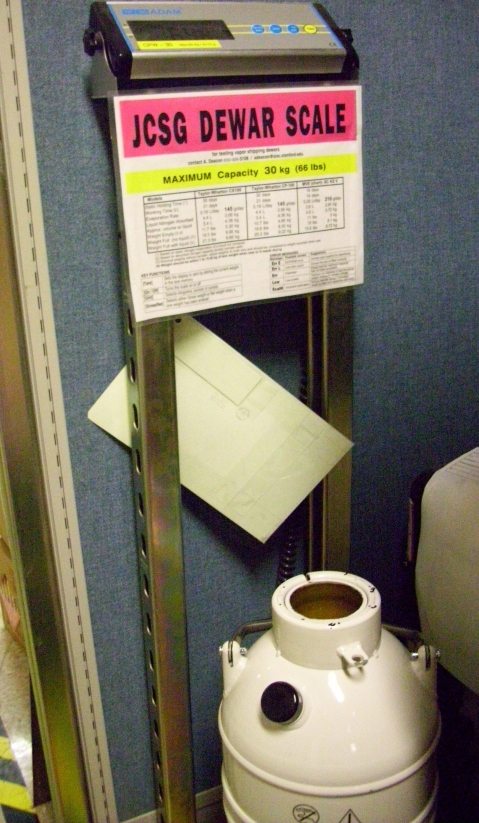

Use a balance similar to an

Adam Equipment CPWplus 35P to determine the empty weight of the dewar.

If the dewar is new, mark the weight on the side of the dewar with permanent

marker. This weight will be considered the “as new” weight. The dewar is

considered acceptably dry if it weighs within 1 lb of the ‘as new’ weight.

Using a scale similar to an Adam Equipment CPWplus 35p, find the weight

of the shipping with no lid or accessories.

3)

If the “as new” weight is known and the dewar weighs 1 lb more than

the ‘as new’ weight, make sure that the dewar is acceptably dry before

proceeding. Drying can be accelerated by application of a dry nitrogen or

air purge. It may take several days to properly dry the shipping dewar.

4)

If you do not know the ‘as new’ weight, the shipping dewar should be

thoroughly dried and the weight recorded. It may take several days to

properly dry the shipping dewar. To verify the dewar is dry, the weight of

the dewar may be monitored until it no longer decreases during drying. The

dry weight should be recorded on the dewar with a permanent marker.

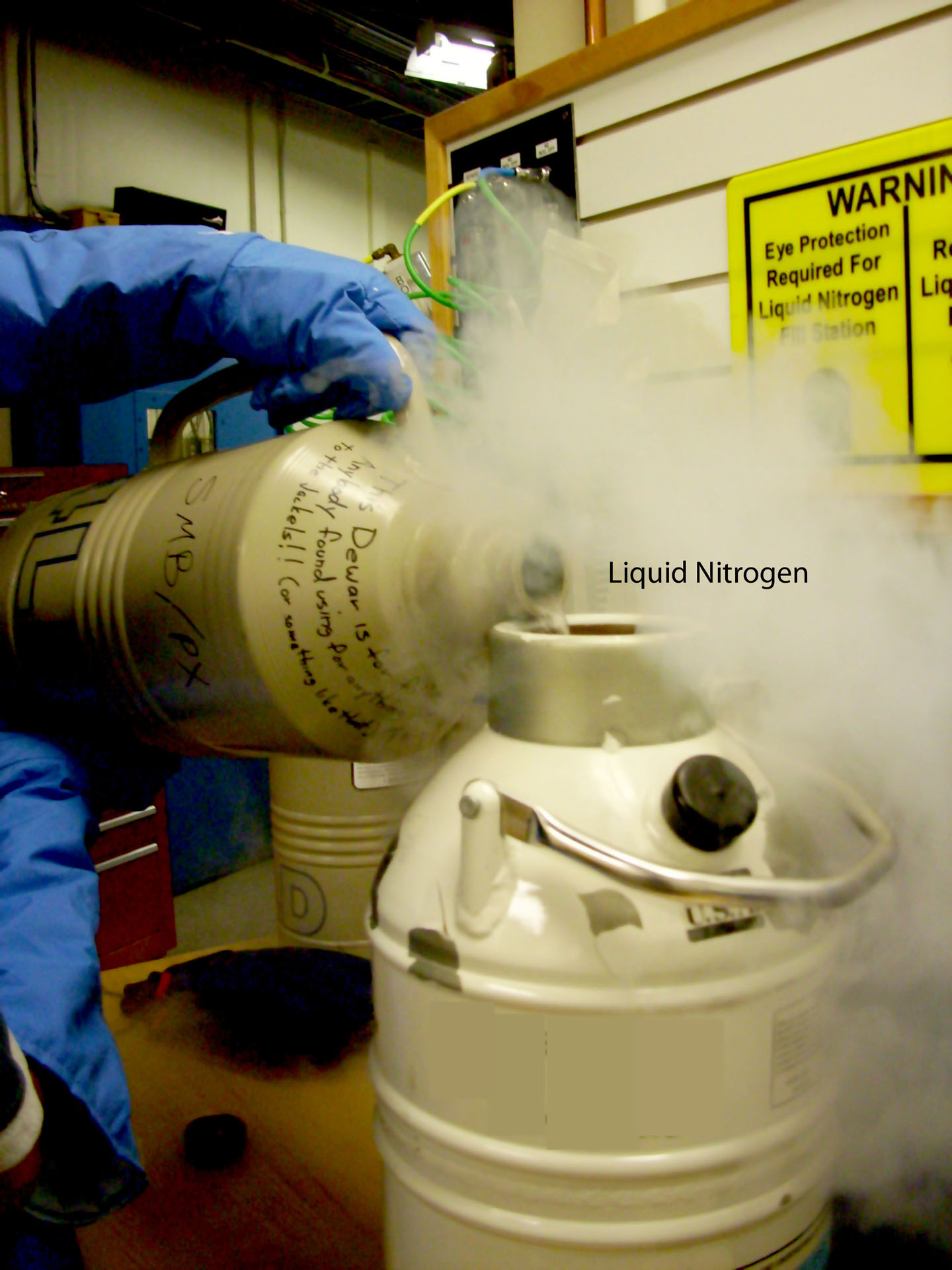

1)

Take the cap off the dewar and pour liquid nitrogen into the dewar until it is full. Avoid spilling on the vacuum plug.

Using a transfer dewar, pour liquid nitrogen into the shipping dewar.

This process may need to be completed 4-5 times to properly charge the

dewar.

2)

Put the cap on the dewar to prevent moisture condensation inside.

3)

Wait 20 minutes.

4)

Repeat steps 1-3 until liquid nitrogen remains at the

top edge of the dewar. This ensures that the absorbent material is

saturated with liquid nitrogen.

5)

Pour out all excess liquid nitrogen. This leaves the absorbent

material fully charged, a requirement for successful dry shipping.

Pour out all excess liquid nitrogen such that only the absorbent material

contains nitrogen.

1)

Wipe the outside of the dewar dry with a cloth.

2)

Wait 2-3 hours.

3)

If excessive condensation has formed on the outside of the dewar (see

pictures below) the vacuum has failed. Do not use this dewar (and contact your manufacturer to have the

dewar repaired).

Excessive condensation (left photo) or frost (right photo) on the outside of

the dewar indicates the dewars insulating vacuum has failed.

This test is designed to measure the vacuum quality of your dewar. A dewar with a good vacuum will retain liquid nitrogen longer than a dewar

with a poor or compromised vacuum.

1)

Properly charge the dewar with liquid nitrogen following the

instructions above (the excess liquid nitrogen does not need to be poured

out of the dewar for this procedure).

2)

Fill the dewar with liquid nitrogen until liquid nitrogen is at the

top edge of the dewar.

3)

Place a meter stick into the dewar to measure the level of liquid

nitrogen in mm. Record the value on the meter stick. Remember to

put the cap back on the dewar to prevent moisture condensation inside the

dewar.

Firs

Tip: Use a wooden measuring stick to measure the level, then take it out of the dewar and shake it

around. You will notice frost or condensation on the places where the measuring

stick had contact with liquid nitrogen. Look for the highest point of

condensation

and record this value as the height of liquid nitrogen in the dewar.

4)

Wait 24 hours

5)

Remove cap from dewar and repeat steps 3.

6)

If the level of liquid nitrogen decreases by 150 mm in 24 hours (or

if it loses more than 100 mm in 16 hours) the dewar vacuum may be

insufficient or dewar enclosure may be damaged (for example the connection

between the dewar neck and body may be ruptured) Inspect the

dewar for damage. This dewar should not be used for dry-shipping.

This test is designed to measure the quality of your dewar's absorbent

material. A dewar that performs well in this test will be dry and thus have the

capacity absorb a proper amount of liquid nitrogen into the absorbent material.

1)

Find the empty weight of the dewar following the instructions above.

2)

Fully charge the dewar following the instructions above. Pour out any excess liquid nitrogen.

3)

Measure the weight of the dewar without the lid (and remove any cassettes, canisters, Teflon rings, etc.).

a.

Subtract the weight of the charged dewar with the weight of the dewar

when it is empty and dry. This weight represents the amount of liquid

nitrogen retained by the absorbent material.

i.

For Taylor Wharton CX-100, the absorbent material should hold 4.4

L of liquid nitrogen corresponding to a weight increase of 3.6 kg over the dry

weight. According the manufacturer, this is equivalent to a working time

of 21 days (if the vacuum has not been compromised).

ii.

For the MVE SC4/2, the absorbent material should hold about 3.8 L

of liquid nitrogen or the weight should increase by 3.1 kg over the dry

weight. According the manufacturer, this is equivalent to a working time

of 14 days (if the vacuum has not been compromised).

b.

If the weight of the liquid nitrogen retained is less than the amount

specified above, the holding time of the dewar is reduced. This can happen

if absorbent material contains a lot of moisture or if the absorbent

material has been damaged and a portion lost. If the amount of

liquid nitrogen retained by the dewar is low, the dewar should be

dried and the above measurements repeated.

c. For dewars with good vacuum

quality, the working time

for the dewar may be calculated by multiplying the ideal working time (21

days for the CX100 and 14 days for the SC4/2) by the ratio of the measured

mass of the liquid nitrogen retained by the shipping dewar divided by the

ideal mass of liquid nitrogen that should be retained (3.6 kg for a CX100 or

3.1 kg for a MVC SC4/2). Note: The holding time

may be further reduced if the vacuum inside the dewar is of insufficient

quality as determined by "the liquid nitrogen loss level test" described in

the previous section.

(your dewar working time in days) = (manufacturer

specified working time in days) x (the amount of liquid nitrogen

retained by your dewar in kg) / (the ideal amount of retained liquid

nitrogen in kg)

If your dewar does not have 10 days of

sufficient working time and good vacuum quality, do not use it to ship samples to SSRL.

|